In 1909 Koenitz Porcelain was founded with four circular kilns .The first products - cups, mugs, bowls and tea sieves - were mainly shipped to England

1909

1912

Even 1912 the company had to expand because of the rising demand and became known as the Koenitz Porcelain Factory Gebrüder Metzel.

During the following decades the company won many new and international markets because of a changed company concept. The Koenitz Porcelain Factory was one of leading medium-sized companies of the region.

1948

1948 the company was taken over by the Soviet A.G. Ceramic Factory Hermsdorf to produces only technical porcelain. In 1951, because of the discontinuation of reparation payments KOENITZ became public property but was still a part of the Ceramic Factory Hermsdorf. Since 1954 the factory produces again household porcelain in its own direction.

1962

The KOENITZ Porcelain factory and the porcelain factory of Kahla fused together to "United Porcelain Factories Koenitz-Kahla", in 1962. During this time there was a common back stamp.

At the beginning of the 1970th the name KOENITZ disappeared for the back stamp because even more porcelain factories joined together to combine Kahla. For example: Volksted, Uhlstädt or Garsitz near Königsee.

1984

Between 1984 and 1985 investments made sure that the most modern assembly line of mugs came into being in Koenitz. This assembly line goes into use in December 1985.

KOENITZ was one of the few porcelain factories besides Kahla which continued after the turn 1989.

Under the Trust Management, the company created its own range of products, such as coffee mugs, children's sets, seasonal items for Easter and Christmas as well as customized items. Könitz quickly re-established itself on international markets and exported goods to Holland, Israel, Italy, Norway, Austria and the U.S.

1993 - KÖNITZ Porcelain is taken over by Turpin Rosenthal

After a career in the porcelain sector (Rosenthal AG), in the furniture trade (IKEA of Sweden) and seven years working in the USA, the current managing director Turpin Rosenthal returned to Germany in the post-reunification years. His wealth of experience combined with entrepreneurial thinking make him look for new fields of activity in the early 90s. "Actually, I had promised myself not to work in the porcelain industry," says Turpin Rosenthal. It is an industry characterized by high craftsmanship and especially low-cost suppliers from Eastern Europe and other countries with low labor costs seem to have strategic advantages here. "With the Rosenthal name, however, I was always offered companies in the porcelain industry that were on the market," he says.

Finally, in the fall of 1993, KÖNITZ Porzellan GmbH. The factory was interesting in that it was a relatively highly automated top cup factory of the former VEB Kahla - Triptis - Ilmenau. In the GDR, the specialization of the individual factories was strongly promoted, so Kahla produced mainly plates and hollow and cast parts and KÖNITZ, precisely with four cup cycle lines was the most modern top cup factory in East Germany up to that time. It produced all cups for this GDR combine. The possibility of producing an article in a highly modernized way and the fact that in the mid-90s there was still no cup specialist in continental Europe - the only exception was a classic English bone china supplier - made Turpin Rosenthal rethink. "Would it be possible to produce the basic article, i.e. the cup, in a basic automated way and thus in a way that could be produced in Germany in the long term, and to design the marketing in a completely new way that was atypical for the porcelain industry?"

Based on this idea, Turpin Rosenthal saw opportunities and negotiated with the Treuhand for the purchase of the company. Together with the then managing director, the new business policy was developed. With the support of the media, for example an appearance with the talk show host of the time, Thomas Gottschalk, the first successful PR steps were also taken.

The first major setback was the legal conditions. Now, at the time, it was the case that former owners - if they had an interest in taking over their old company - would always have priority. The heirs of the former Metzel family, i.e. the founding family, originally had no interest in the company.

However, when Turpin Rosenthal and its new business idea became public, the owning family changed its attitude and demanded the sudden return of the company. Now it was also the case that in those days the acquiring party would still receive loss compensation from the Treuhand for a few months. This was to bridge the start-up losses during the period in which investments and innovations were being implemented and the company was to be made fit for the market. However, since the purchase of the company by Turpin Rosenthal was called into question by the interests of the former owners, ownership did not pass to Turpin Rosenthal for what was now a very long time. Rather, it looked as if the former owner family would take over production together with a porcelain company from Upper Franconia. This would have meant an early end for the new entrepreneur.

1994

A first crisis

It happened in 1994 that the then Treuhand, ultimately a sales and promotion institution of the state, was renamed BVS. This change of name was accompanied by a new mission of this state institution. It was no longer to promote companies, but to handle contracts. In the situation in which KÖNITZ Porzellan found itself, this meant that an extension or renewal of the grant periods would no longer be an option.

One obstacle now followed the next. First of all, the Treuhand, which had become BVS, was obliged to negotiate with the former owners. As a result, privatization and the associated investments could not be implemented. The subsidies negotiated with the Treuhand therefore went into loss compensation long before the planned investment was implemented, and there was no longer any thought of a further investment period. In the meantime, the Metzel family, together with the works councils and the competitor, had formed an alliance that promised the employees a golden future.

In contrast to Turpin Rosenthal's plan, there were to be no layoffs. Jobs were to be preserved and large wage increases were to be expected. Turpin, a budding entrepreneur, now found himself surrounded by problems from all sides. BVS, for example, was not offering any further subsidies, which would lead to immediate bankruptcy. The employees had been organized together with the unions to protest against the new owner. For example, the then trade union IG Chemie-Papier-Keramik organized large demonstrations on the plant premises; for example, the entire workforce blocked federal highway 281 on one day to draw attention to the interests of the Metzel Group. At the end of 1994, the Metzel family decided to no longer participate in the KÖNITZ Porzellan company. Why? - it was quite simple: the company was not entitled to any more subsidy months and it would have had to raise actually significant own money for liquidity and investments. The unrealized privatization, or the sale to Turpin Rosenthal or the group around the Metzel family fighting over the company, led to a foreseeable end of the subsidies and thus a foreseeable bankruptcy of the company. As a young entrepreneur, Turpin Rosenthal was also no longer able to access liquid funds in order to implement a major investment after a delay of 1.5 years.

1996

Was that the end?

No! There was a plan to reach the goal in another way. Like a sinking ship, Turpin Rosenthal and the then warehouse and later production manager Reinhard Krauße had to sell everything that was not nailed down.

Furnaces, tractors and many items of equipment and plant in order to pay the redundancy payments to the employees required in the event of staff cuts. After six months of cutbacks, the once proud company, which had employed over 300 people before the fall of the Berlin Wall, was down to just 8 employees.

Likewise, the entire production was shut down and only stocks were sold and former plants were managed.

But as it is so often the case - a crisis often leads to innovative business models. In this case, the cup cycle lines or the molds were handed over to nearby, initially Czech porcelain plants. These continued to produce the blanks at that time exclusively for KÖNITZ Porzellan.

KÖNITZ Porzellan specialized within the scope of the original conception, but without its own white production, in the sub-markets which had already been envisaged at an early stage and which each required their own market cultivation and product development. On the one hand, the retail trade was served. These were department stores, gift stores and porcelain stores of a certain standard, which sold the KÖNITZ mug as a single gift assortment. At first, the retailers could not do much with a mug without other tableware. But the consumer surprised them. The mug became a great success as a single gift item. Especially when a product like a mug told its own story and thus provided its own gift value. Mugs and cups made of porcelain for tea, coffee and all hot drinks.

At that time, KÖNITZ Porzellan produced with great success, for example, the "Kamasutra" collection or an exclusive Andy Warhol collection - the most important pop artist from America at that time with whom Turpin Rosenthal concluded an exclusive license agreement. Another important submarket was cups and mugs as promotional or merchandising items. Companies were given the opportunity to produce mugs under their own brand to support their advertising and PR activities or as merchandising articles. Demanding customers found in KÖNITZ a partner who could realize their wishes on the highest level.

The market for custom-made cups already existed before, but only with a cheap logo quality and poor printing. KÖNITZ Porzellan as a real porcelain manufacturer was able to offer a much more sophisticated product, as this had the quality of good household porcelain. KÖNITZ cups did not scratch or fade and the colors met the highest standards.

Early on, important partners such as Porsche, Melitta, Postbank or the Louvre Paris, the MOMA New York etc. decided to have their cups custom-made by KÖNITZ Porcelain. The former 8 employees of the crisis period very quickly became a stately porcelain company again. Already in 1996 KÖNITZ Porzellan had 50 employees again, in 1998 80 employees and could take over the Wiedemannsche Druckerei AG, Thuringia's oldest company.

1998

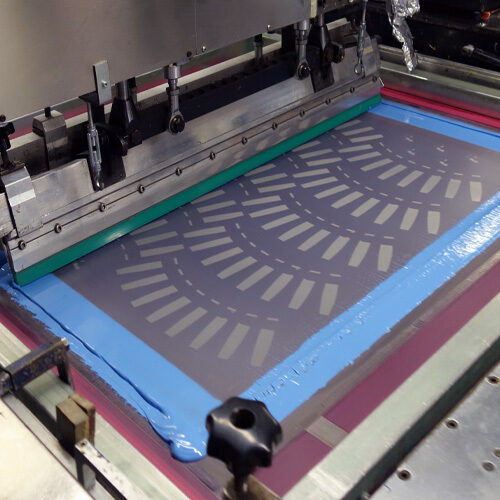

This history is also interesting: Wiedemannsche Druckerei AG had traditionally been a print shop, but by the 19th century it had specialized in the production of burn-in print images. The company was founded in 1673 as a court book printer. Since 1880, the company specialized in burn-in screen patterns or ceramic color prints, also called decals. The print shop developed into the leading supplier of sophisticated prints for the porcelain industry.

With the general decline of the German porcelain industry, the insolvency of Kahla Porzellan, Graf Henneberg and other factories, the market collapsed and the West German owner of the printing company had no interest in keeping the company on the market.

KÖNITZ Porzellan found, even in this early period of the 1990s, that the production of high-quality printed images was the company's true technical achievement. High quality prints, sophisticated colors, unusual effects were why customers bought mugs from KÖNITZ. The decorations, or the surface of the mug, transformed the blank into a desirable product.

Thus, the purchase by KÖNITZ Porzellan saved the Wiedemann printing plant and prevented its closure. At the same time, KÖNITZ was able to stabilize its most important upstream supplier. The cooperation of Wiedemannsche Druckerei with KÖNITZ Porzellan as a partner for product development, sales and especially decoration led to a situation in which KÖNITZ Porzellan GmbH was able to be extremely competitive and to grow with attractive products. Over the years this enabled the creation of jobs and also the acquisition of other companies. Subsidiaries were also founded abroad in the USA, Australia and Thailand. Today, the name KÖNITZ is known throughout the developed world. You can find KÖNITZ mugs at leading retailers in New York, Tokyo, Singapore, Paris and Berlin.

From its origins in Thuringia, KÖNITZ has become a leading manufacturer of coffee mugs for the world.

2018

2018 KOENITZ get the "Promotional Grift Award" for our "Selfmade Mug" - a porcelain mug with a new printing surface you can paint on with pencils. But don't worry - your little artwork can be washed off. "It's an absolutely innovative product for the custom design", the jury means. This mug represents new developments with which one KOENITZ will be more poplular in retail and custom design.

Even 2009 KOENITZ present the lasting "To Go mug" made of porcelain. Also licensed motifs from "Guess how much I love you" (launch 2007) over "The little Prince" (launch 2011) to "Asterix&Obelix" (launch 2015) enrich the mug portfolio and became to bestsellers.

One of the best sold new hit of 2017 was the "Coffee for One" because of the actual trend to filter your coffee by hand for a better taste and to protect the environment.

111 Jahre

KÖNITZ porcelain in the region

KÖNITZ the mug specialist holds up the flag for the region worldwide. The coffee mugs with the lettering "KÖNITZ" can be found all over the world, but of course also in the factory outlet in Könitz. Here everyone can look at the products that make us famous all over the world and even buy them at a special price. Here you can see custom-made products and the brand assortment in its entirety. Smallest mistakes allow us to sell these products especially cheap and therefore we are with the factory outlet also an attraction for the whole region.

2022

QR-Mug-Digital

KÖNITZ Porcelain manufactures QR-Mug-Digital - the world's first usable, interactive and communicative mug. The QR-Mug-Digital technology is patented and allow to combine the features of the ancient porcelain industry with the most modern communication possibilities.

2022

KÖNITZ Porcelain produces the first cups using the digital printing process

With a simplified prepress process, KÖNITZ Porzellan is able to produce high-quality, scratch-resistant and surface-resistant photo and multicolor prints with a specific color space on porcelain at low cost. In this way, Könitz produces a budget-friendly and, in contrast to sublimation, long-term usable low-cost reproduction option for multicolor photo mugs.

2023

350 years Wiedemannsche Druckerei

Wiedemannsche Druckerei AG produced decals for glass, ceramics and porcelain. Next to colorful images we are able to print special surfaces such as wood, steel, oil painting or structures. Since 1673 our enterprise looks back on a long tradition as lithographic art center in Thuringia and Saxonia. Our strengths are the conversion of multi color and complex design-orientated decals. As one of the few companies around, our coworkers knows still today the traditional hand lithography. Combined with the employment of modern electronic image processing in the pressure preliminary stage, we can serve our customers a broad spectrum from conceptional design solutions up to exclusive decoration.